The 6-Second Trick For Plant Conveyors And Systems

Table of ContentsIndicators on Plant Conveyors And Systems You Need To KnowThings about Plant Conveyors And SystemsThe Greatest Guide To Plant Conveyors And SystemsThe Best Strategy To Use For Plant Conveyors And SystemsPlant Conveyors And Systems Things To Know Before You BuyExamine This Report on Plant Conveyors And Systems

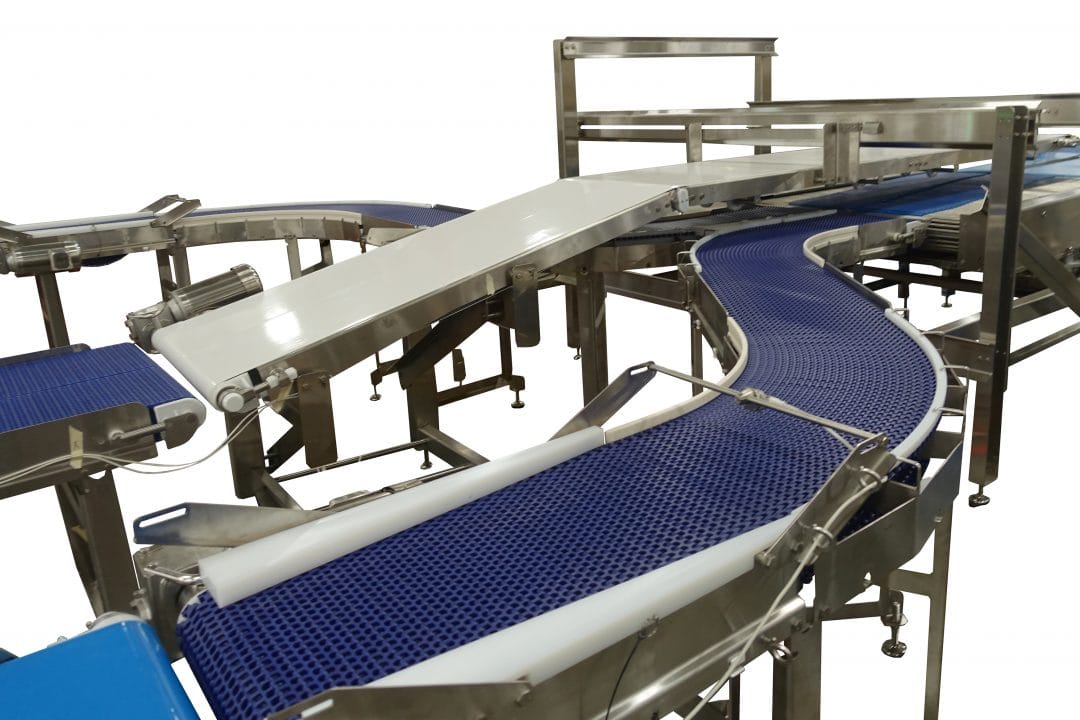

Carryback prevails in all belt systems and also is one of the major problems that causes belt breakdowns. Drive: The drive for the belt can be found in numerous placements in the sharing system. For many belt conveyors, the drive is situated at the discharge or head of the belt - Plant Conveyors and Systems.AC motors are typically used to power the sheave that moves the belt. Chapter 5 Conveyor System Applications As automation and also production have actually come to be extra technologically advanced, conveyors have quickly become a crucial part of product processing and motion as well as enhancing the speed of numerous manufacturing procedures.

Conveyors transportation the piece into the high temperature furnaces for the sintering procedure. Product packaging: A product packaging conveyor is created to aid with item packaging, such as placing ended up items in containers, efficient labeling, or prep work of items for shipping. The feature of a packaging conveyor system is to relocate items from completion and setting up for shipment.

Plant Conveyors And Systems for Dummies

Extract conveyors are used to remove molded pieces from journalism line or on various other operations. Flight terminal: Though flight terminals have individuals relocating conveyors, the primary conveying system is for travel luggage handling, which accelerates the procedure of obtaining travel luggage from the checkin counter to the plane and off the plane to baggage pickup.

Though mining conveyors vary in dimension as well as length, the bulk of them get on an incline as well as relocate a number of lots of material. They need to be uniformly filled to prevent splilling or vacant spaces. Depending on the style, they run extremely rapidly approximately 100 fpm. Mining Conveyor Automotive: The automobile sector uses numerous ranges of conveyors for product handling.

The one variable that makes them special is the requirement to satisfy governmental laws for sanitation as well as tidiness. Printing: Printing conveyors, for screen printing, use a conveyor dryer procedure for drying out display published product. Though there are other methods for drying out screen prints, conveyor dryers are utilized for big quantity manufacturing and also come in several ranges.

Some Ideas on Plant Conveyors And Systems You Need To Know

Phase Six Benefits of a Conveying System Conveyors have ended up being an integral part of manufacturing, mining, manufacturing, and also ending up procedures. They boost effectiveness and help in reducing labor expenses. The usage of conveyors has caused greater quantity, boosted production, and avoidance of injuries. No matter the industry, conveyors have actually been shown to be a boost for production procedures.

Continuous Procedure: Materials are continually packed as well as unloaded for extended periods of time without disruption or stoppage. Automated Unloading: Conveyors can be made to automatically unload materials without the requirement for manual work. Control of Motion: Conveying systems have rate controls to keep an eye on just how swiftly products relocate along the system, which eliminates the worry for handling concerns or damage.

Excitement About Plant Conveyors And Systems

The photo below is of a safety and security cable pick up conveyors. High Volume: Conveyors belong of an automated system with the ability of relocating hundreds or hundreds of lots of material check it out per hr or in a day. Chapter Seven Conveying System Malfunctions There are malfunctions that can take place in a communicating system that is constantly in usage.

Conveying System Malfunctions Mistracking Mistracking is also called belt drift, where the belt wanders to one side. A misaligned belt can seriously harm the belt by uneven wear or damages products on the belt. The photo listed below is of a belt that has actually wandered to the left. Confiscated Rollers Part of the mistracking trouble might be connected with a taken roller, which can cause sharp edges that would close down the system.

Slippage Slippage on a belt conveyor can take place because of tension being too expensive or reduced, which can cause extending and view website conveyor belt slippage. Obstruction Conveyor systems are designed to run continually without disturbance or stoppage. Any kind of form of obstruction can be damaging to the system and also cause major fixings.

Plant Conveyors And Systems for Beginners

The most typical is when product stays with the belt and goes past the transfer point and diminishes. Carryback can be seen at the bottom of the image listed below. Splilling When a belt conveyor is overloaded, or also jam-packed, materials can diminish the sides. This can occur when employees are not educated properly, or there is a trouble up the line.

Screw Conveyors Tiredness in a screw conveyor occurs when there is build up in the pipe as the conveyor turns. In that gap, material accumulates and also solidifies.

Facts About Plant Conveyors And Systems Uncovered

Repair Service or Replace Deciding to change a part on a system has a number of cost aspects, such as the downtime for the system, discovering the ideal element, and also hiring an expert to do the replacement. This expense more information can be countered with routine maintenance and also tracking of the system. Motor The key part of a conveying system is its electric motor (Plant Conveyors and Systems).

The temperature level of the motor need to never ever surpass its advised operating temperature. They never ever need repair if they are regularly checked and maintained.